Computerized paint matching revolutionizes auto body repairs by offering a fast, precise, and consistent alternative to manual color analysis. Leveraging AI and computer vision, these systems streamline vehicle restoration processes, enhance finishes, reduce waste, and optimize production lines for professional bodyshops serving high-volume customers. While manual techniques remain suitable for smaller, on-site repairs, computerized paint matching is the preferred method for large-scale operations like paintless dent repair due to its superior accuracy and speed.

In the realm of automotive repair and refinishing, accurate paint matching is paramount for quality finishes. This article delves into the contrasting approaches of manual and computerized paint matching methods. While traditional manual techniques rely on expert judgment and color charts, the rise of computerized paint matching technology promises enhanced precision through advanced algorithms and spectral analysis. We compare their accuracies, applications, and implications in today’s digital era, highlighting the game-changer potential of computerized solutions.

- Understanding Manual Paint Matching: The Traditional Approach

- The Rise of Computerized Paint Matching Technology

- Comparing Accuracies and Applications: Manual vs. Computerized Methods

Understanding Manual Paint Matching: The Traditional Approach

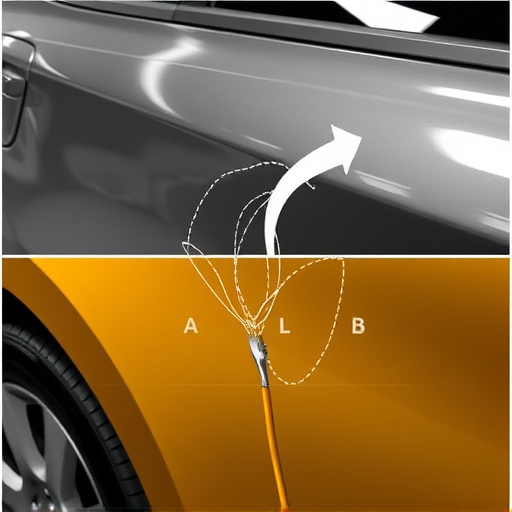

In the realm of auto body repairs, paint matching has long been a meticulous art practiced at every auto repair shop and collision repair shop. The traditional method, often referred to as manual paint matching, involves skilled technicians who meticulously analyze and match colors by eye. This manual paint matching process begins with examining the damaged area to determine the specific shade and tone of the existing paint. Technicians then search through a vast array of paint samples or swatches until they find an exact or sufficiently close match. The challenge lies in replicating the subtleties of color, including undertones, which can be incredibly complex, especially for auto frame repair professionals trying to blend new paint with the original finish.

This traditional approach demands a keen eye, extensive experience, and a vast knowledge of color theory. It is a time-consuming process that requires the technician to be highly skilled in their craft. Despite the efforts involved, manual matching may not always result in an identical match, especially for unique or discontinued colors, which can be a concern for customers and collision repair shops aiming for flawless restoration. This is where computerized paint matching comes into play as a modern alternative.

The Rise of Computerized Paint Matching Technology

The evolution of technology has significantly impacted various industries, and the paint industry is no exception. With advancements in artificial intelligence and computer vision, computerized paint matching technology has emerged as a game-changer in the field of auto body restoration and car collision repair. This innovative approach offers precision and efficiency previously unattainable with manual methods.

Computerized paint matching systems utilize sophisticated algorithms to analyze and match colors with incredible accuracy. By capturing detailed specifications, these technologies can precisely duplicate original paint shades, ensuring a seamless fit during car bodywork repairs or custom paint jobs. This modern solution not only saves time but also minimizes the risk of human error, resulting in superior finishes for vehicles undergoing auto body restoration processes.

Comparing Accuracies and Applications: Manual vs. Computerized Methods

When comparing accuracies between manual and computerized paint matching methods, it’s evident that computerized paint matching systems have an edge in terms of precision and speed. Manual methods, often relying on human observation and estimation, can be subjective and inconsistent. Computerized systems, on the other hand, use advanced algorithms and spectrophotometers to analyze and match colors precisely, minimizing variations across different batches and conditions.

The applications of these methods also differ significantly. Car bodywork services and vehicle repair shops commonly employ manual techniques for quick, on-site repairs due to their accessibility and the need for flexibility in remote locations. However, for large-scale operations involving paintless dent repair, computerized paint matching is the preferred choice. This method ensures consistent results, reduces waste, and streamlines production lines, making it ideal for professional bodyshops catering to high-volume customers.

In the realm of paint matching, the traditional manual method has been joined by a modern game changer: computerized paint matching technology. While understanding the nuances of manual techniques remains valuable, the rise of computerization offers enhanced accuracy and efficiency in various applications. Computerized systems, leveraging advanced algorithms and vast databases, ensure precise color matching and streamline processes, making them a vibrant and bustling choice for professionals and enthusiasts alike. In terms of accuracy, application, and convenience, computerized paint matching is certainly leaving its indelible mark on the industry.