Computerized paint matching, leveraging scanners and software, revolutionizes auto painting and restoration by accurately replicating original factory finishes. This technology, crucial in collision repair, captures detailed surface data including shape, contours, and hue to achieve perfect color reproduction, surpassing traditional methods for speed and accuracy. Technicians use scanners to capture color profiles of damaged areas, inputting data into systems that quickly match it with an extensive paint database for seamless repairs.

In the realm of automotive and industrial restoration, achieving precise computerized paint matching is paramount. Scanners have emerged as indispensable tools for technicians, revolutionizing the way they ensure flawless color accuracy. This article delves into the intricacies of computerized paint matching, highlighting the fundamental role scanners play in this advanced process. From understanding the basics to exploring the step-by-step techniques employed by experts, we unravel the secrets behind achieving perfect paint harmony.

- Understanding Computerized Paint Matching: A Basic Overview

- The Role of Scanners in Achieving Precise Color Match

- Step-by-Step: How Technicians Utilize Scanners for Paint Matching

Understanding Computerized Paint Matching: A Basic Overview

Computerized paint matching is a revolutionary technology that has transformed the process of auto painting and restoration. This advanced system utilizes scanners and sophisticated software to ensure precise color reproduction, making it an indispensable tool in automotive collision repair and beyond. By capturing detailed data about the surface’s characteristics, including its shape, contours, and unique color hues, these scanners create a digital blueprint for perfect paint matching.

This technology goes beyond mere color identification. It takes into account various factors like the original factory finish, environmental conditions during production, and even age-related changes, ensuring that the new paint closely replicates the original finish. Whether it’s for repairing minor dents or replacing entire panels in auto glass repair scenarios, computerized paint matching offers a level of accuracy and efficiency that traditional methods struggle to match, making it a game-changer in the industry.

The Role of Scanners in Achieving Precise Color Match

In the realm of auto frame repair and auto collision repair, achieving precise computerized paint matching is paramount for a seamless restoration. Scanners play a pivotal role in this process by capturing detailed color profiles of damaged or worn surfaces. These advanced tools enable technicians to input exact shade data into computer systems, ensuring that every hue matches perfectly during the auto bodywork process.

By utilizing scanners, technicians can bypass the traditional, time-consuming method of manual matching. This not only expedites repairs but also enhances accuracy. The ability to digitally capture and reproduce colors with such precision is a game-changer in the industry, allowing for impeccable results in both auto frame repair and auto collision repair services.

Step-by-Step: How Technicians Utilize Scanners for Paint Matching

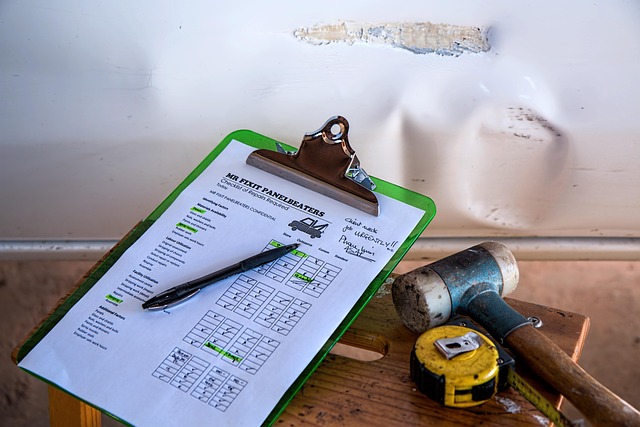

Technicians in auto repair shops and collision centers rely on scanners for computerized paint matching, a precise process that ensures perfect color accuracy during car collision repair. The journey begins with the technician carefully inspecting the damaged area, noting the extent of the dent or scratch. They then prepare the surface by cleaning it thoroughly to eliminate any contaminants.

Next, they position the scanner over the affected panel, ensuring optimal contact for accurate readings. The scanner emits light across a broad spectrum, capturing detailed information about the paint’s color and composition. This data is then fed into a sophisticated computer system that cross-references it with an extensive database of available paints. Within seconds, the computerized paint matching software provides a precise match, allowing technicians to select the exact shade required for the car collision repair, ensuring a seamless finish.

In conclusion, technicians play a vital role in achieving accurate computerized paint matching using advanced scanners. By meticulously capturing and analyzing color data, they ensure that the reproduced shade is an indelible testament to the original. This process revolutionizes the paint industry, enabling swift and precise color identification, ultimately enhancing customer satisfaction.